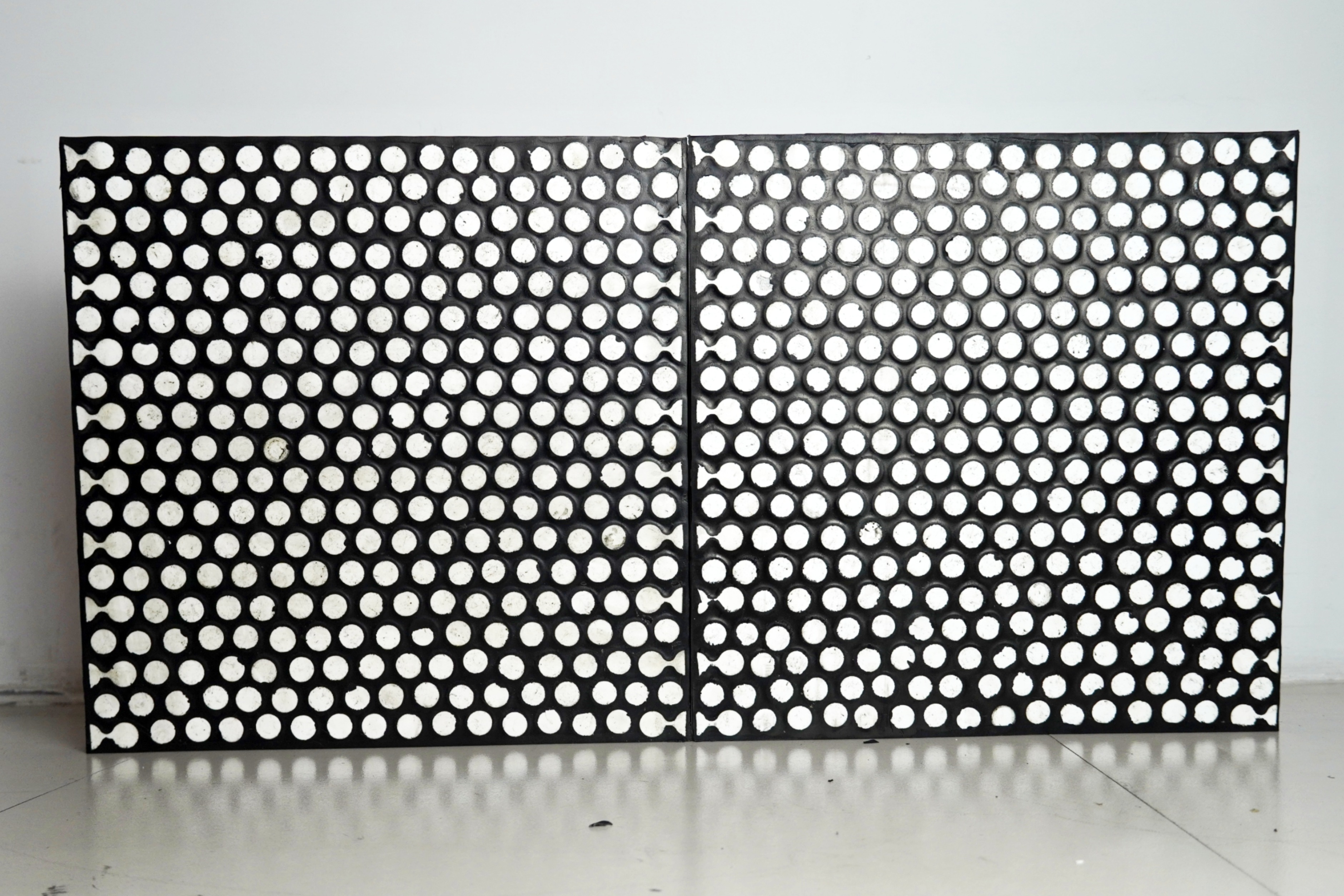

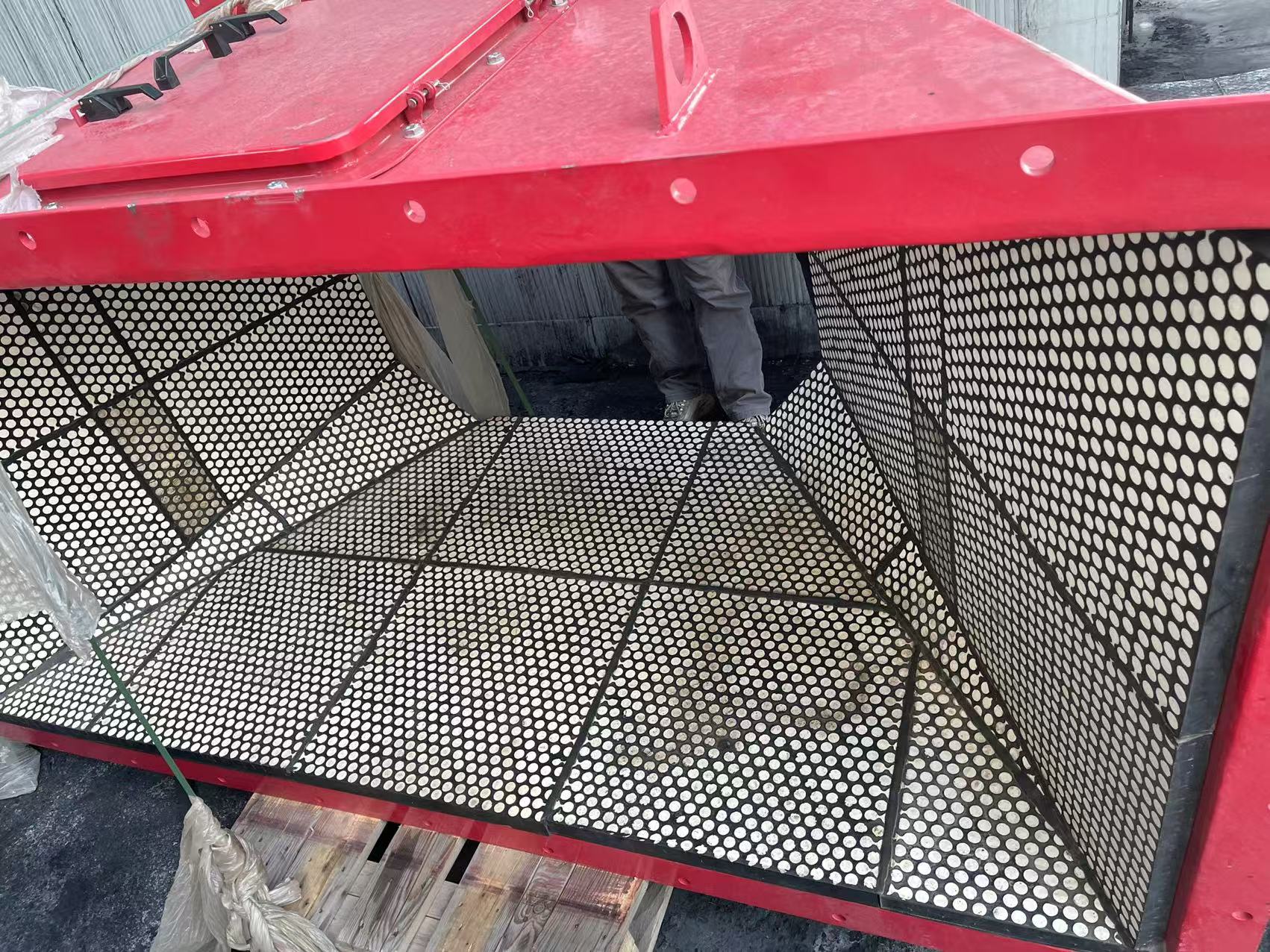

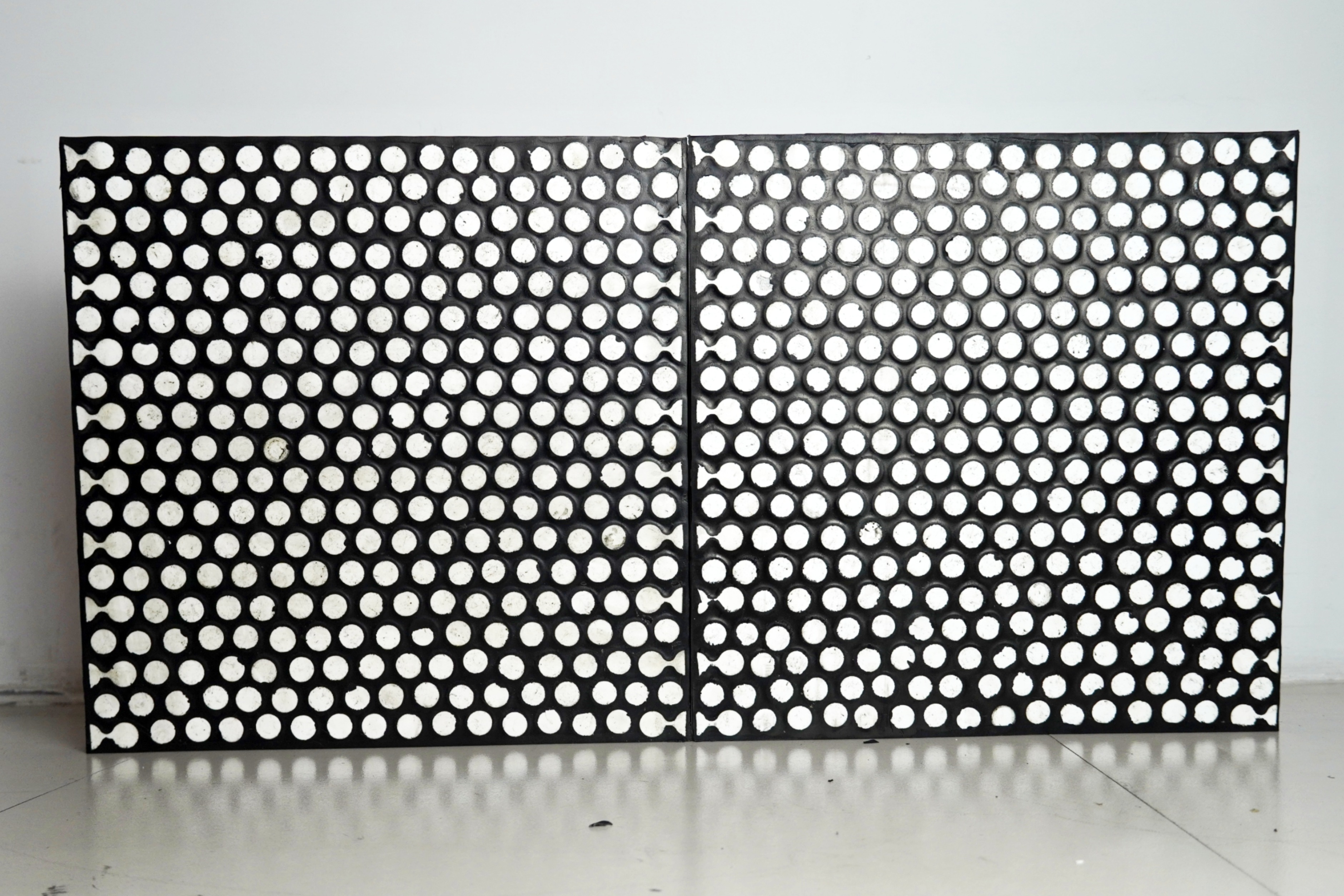

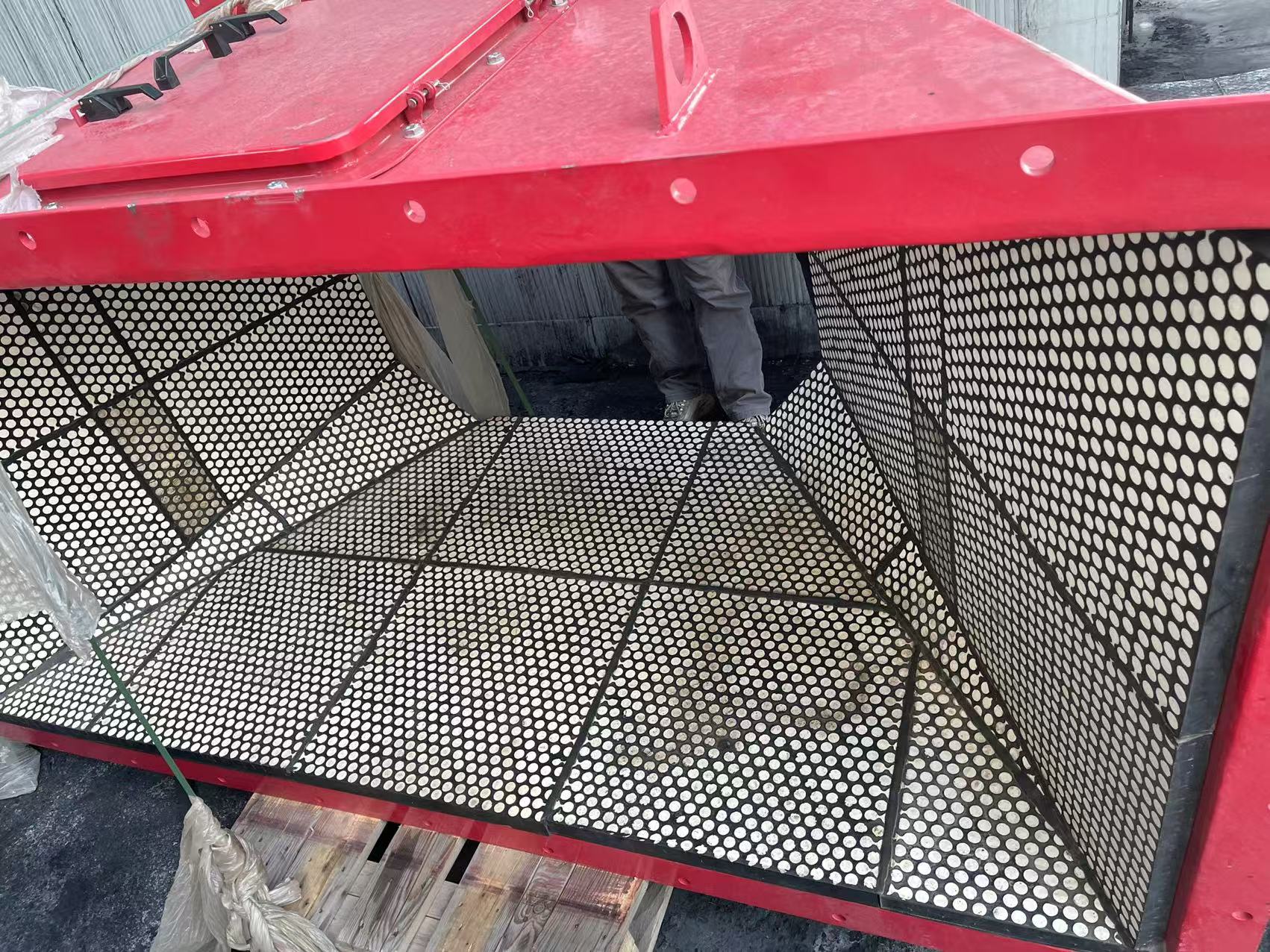

We are pleased to introduce our Ceramic Conveyor Belt Chute Liner, an innovative product designed to enhance the wear resistance and prolong the lifespan of conveyor belts. Typically installed near the chute of conveyor belts, these liners protect the belts and equipment from the abrasion and damage caused by materials, ensuring smooth operation of production lines.

Features and Benefits:

1.High-Quality Ceramic Material: Manufactured from premium ceramic material, our liners possess excellent wear resistance and impact resistance, effectively resisting the abrasion and impact of materials, thus protecting the conveyor belts and equipment.

2.Precision Installation: The liner is precisely designed to be bonded or bolted to the chute position of the conveyor belt, ensuring full adherence to the surface of the belt, preventing loosening or displacement.

3.Chemical Resistance: Ceramic materials exhibit excellent chemical stability, resisting corrosion from acids and alkalis, maintaining long-term stable performance.

4.Extended Lifespan: By effectively reducing the wear of materials on conveyor belts, ceramic liners significantly extend the lifespan of conveyor belts, reducing maintenance and replacement costs.

5.Wide Applicability: Suitable for various types of conveyor belts and materials, including coal, ores, slag, cement, and more, making it an ideal choice for many industrial productions.

Applications:

1.Mining and Quarrying: Used to protect conveyor belts at material discharge points during processing of ores, slag, etc., extending equipment lifespan.

2.Cement and Construction Materials Industry: Applied in conveyor belt systems for handling cement, sand, and other materials, enhancing wear resistance and stability of equipment.

3.Coal Industry: Installed to protect conveyor belts at material discharge points during transportation of coal and coal gangue, reducing equipment maintenance and replacement frequency.

Conclusion:

The Ceramic Conveyor Belt Chute Liner is a high-performance protective equipment designed to improve the wear resistance and stability of conveyor belt systems, prolonging equipment lifespan and reducing maintenance costs. We offer a variety of specifications and sizes of liners, customizable to meet customer needs, ensuring optimal fit and performance, delivering greater value and efficiency to your production lines.

RANGE OF APPLICATION

Easy installation, long service life, good wear resistance, suitable for material transfer, such faster, larger wear areas.

PRODUCT FEATURES

Ceramic is alumina (Al2O3) as the main raw material, with additional other special ingredients, made at high temperature. Widely used in thermal power, steel, smelting, coal, mining, chemical industry, cement, ports and wharfs.

Especially suitable for conveying system of the discharging , pulverizing system, ash, dust removal system, it can reduce the impact of equipment wear.

Size: Can be customized according to need

TECHNICAL PARAMETERS:

Alumina content ≥ 98%

Density ≥ 3.6g/cm3

Hardness of ceramic ≥ 85HRA

Compressive strength ≥ 850Mpa