Product Features:

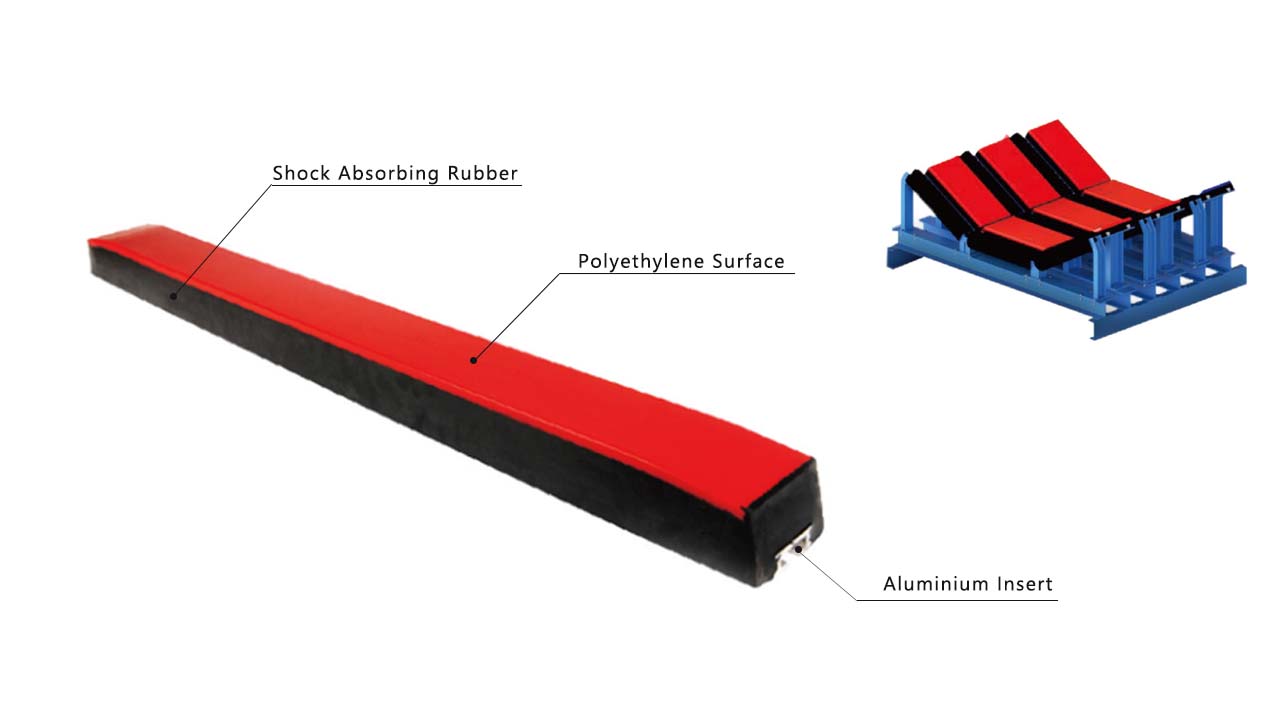

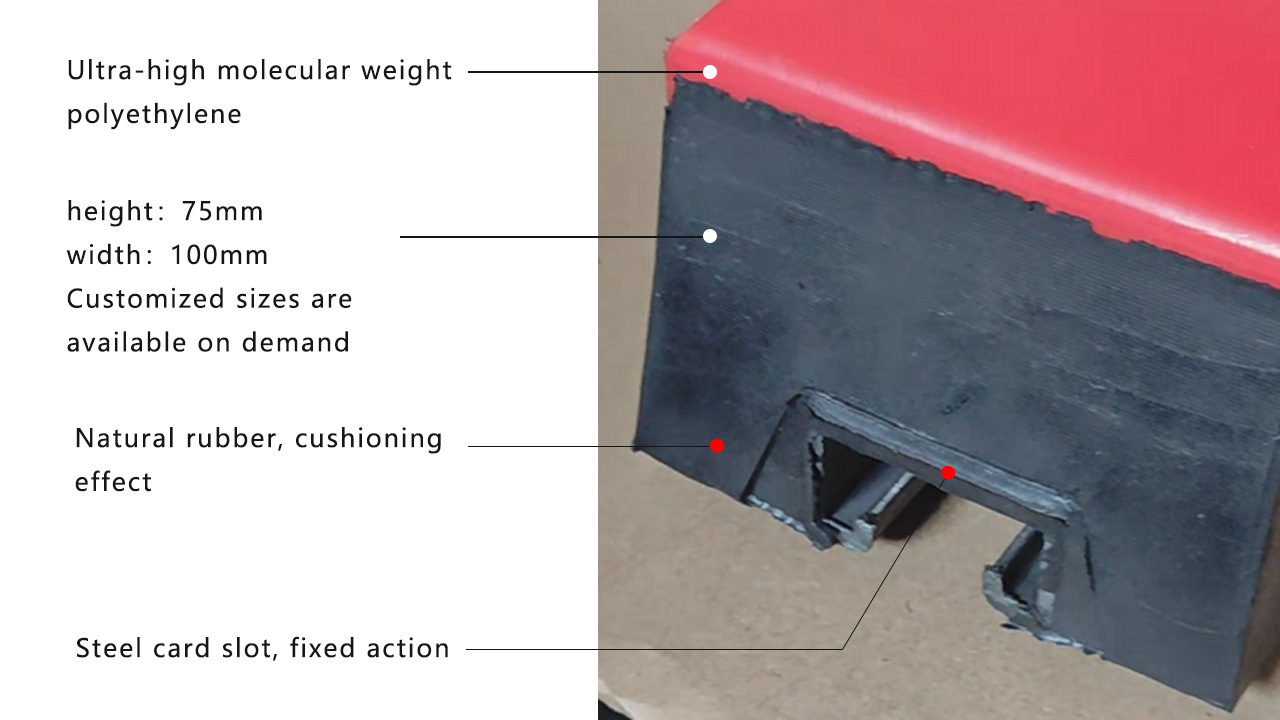

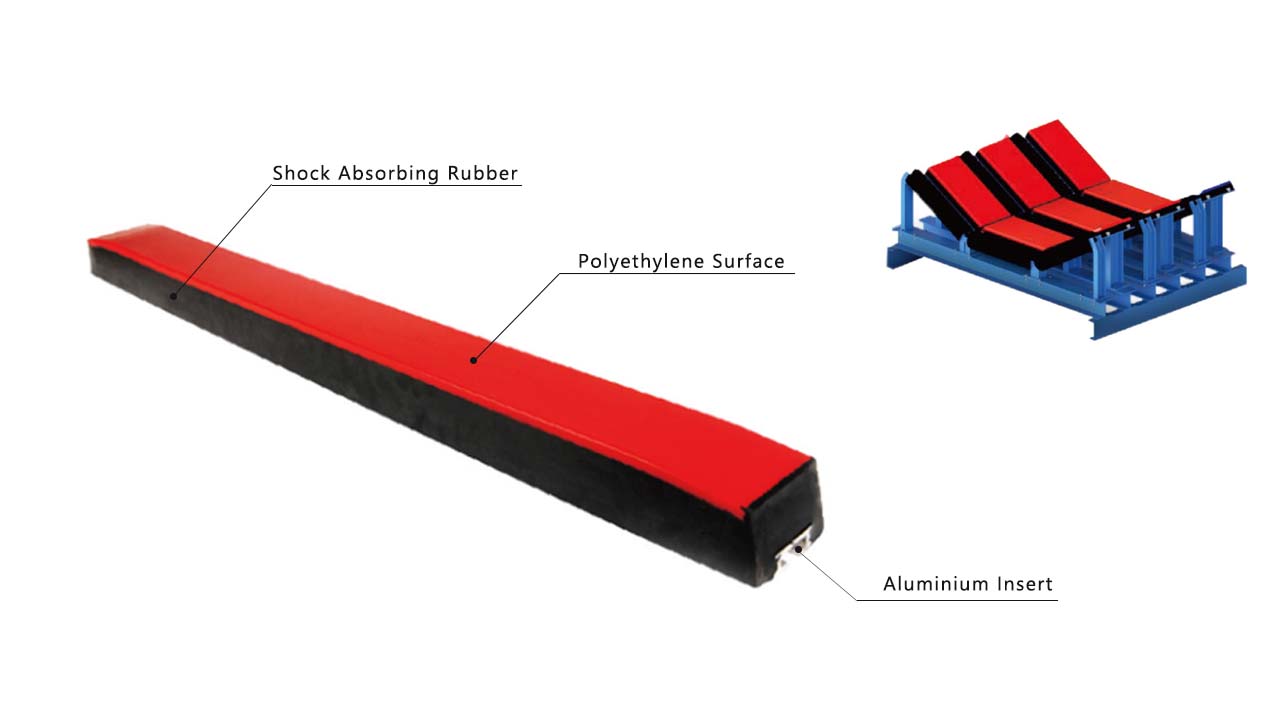

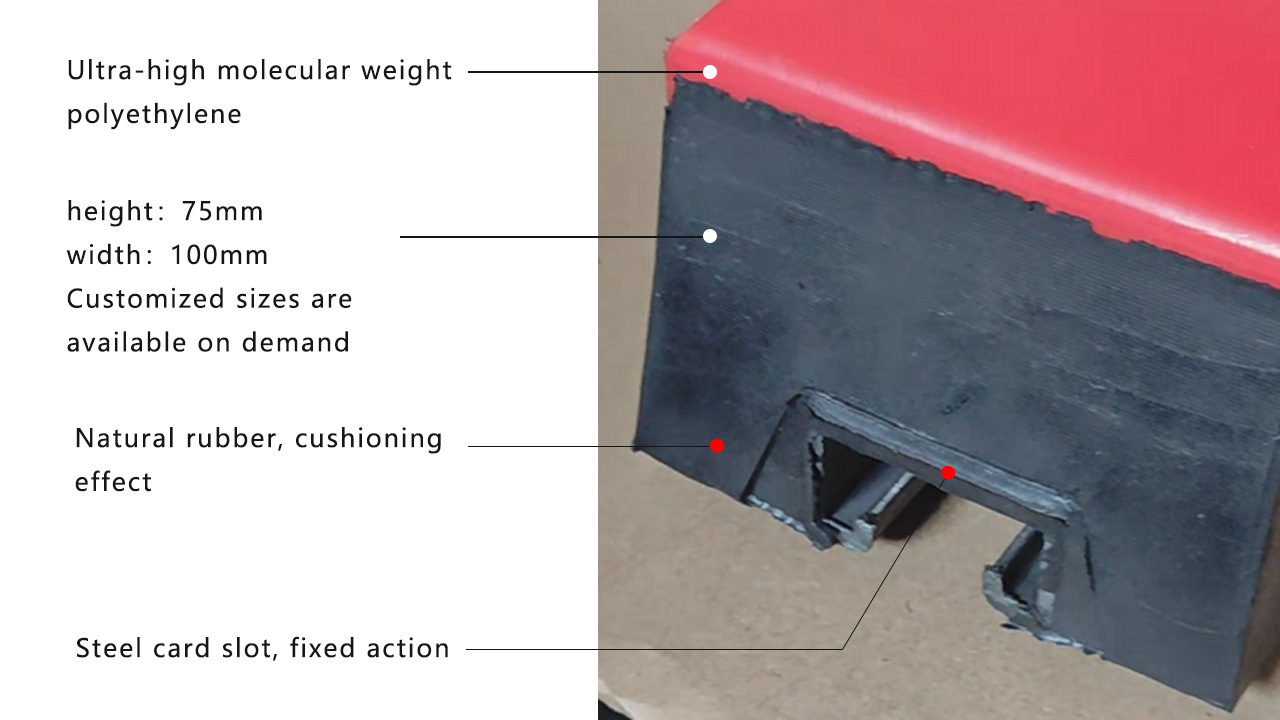

1.Smooth UHMW Polyethylene Surface: Reduces friction between the conveyor belt and the buffer bar, enhancing efficiency.

2.Thickened Red UHMW Polyethylene Layer: Offers broader applications and enhances product durability.

3.High-Performance Special Rubber Layer: Effectively absorbs impact forces when materials fall, ensuring smooth material handling.

4.Prevents Conveyor Belt Damage: The buffer bar's contact with the conveyor belt surface effectively prevents damage.

5.Reduces Maintenance: Even distribution of force during loading reduces the need for maintenance and repairs.

6.Prevents Material Spillage: Eliminates material splashing and leakage caused by uneven force on the conveyor belt.

7.Complete Set with Fasteners: Available in complete sets with fasteners and can be customized in any length-to-height ratio.

8.Durable Construction: Each part of the buffer bar is compactly and firmly combined through hot vulcanization.

9.Fire Retardant: The buffer bar is rated as "V" class fire retardant.

Product Specifications:

10.Main Specifications of Buffer Bar:

11.Buffer Bar Dimensions (mm) | Polyethylene Thickness (mm)

12.50/75 | 100 | 1220 | 12.5

13.50/75 | 100 | 1400 | 12.5

14.50/75 | 100 | 1500 | 12.5

15.50/75 | 100 | 1600 | 12.5

16.50/75 | 100 | 1800 | 12.5

The high-efficiency buffer bar system offers a range of features designed to optimize conveyor belt operations and enhance durability. With a smooth UHMW polyethylene surface to minimize friction, a thickened red UHMW polyethylene layer for extended lifespan, and a high-performance special rubber layer to absorb impact forces, this system ensures smooth material handling while preventing conveyor belt damage.

Furthermore, the even distribution of force during loading reduces maintenance requirements and repairs, while the prevention of material spillage eliminates wastage and cleanup efforts. The buffer bar comes as a complete set with fasteners and can be customized to fit specific length-to-height ratios, ensuring versatility in various conveyor setups. With its durable construction and fire-retardant properties, the buffer bar system stands out as a reliable solution for improving conveyor belt efficiency and longevity.

Impact Bar:

· Impact bar is an important cushion part.

· Slow down the materials on the conveyor belt and the impact damage, avoid sharp objects for tape tearing and scratches.

· Used in belt conveyor material guiding groove, blanking point below the belt.

· Outstanding capability to absorbing impact and low friction coefficient

IMPACT BAR SIZE |

HIGHT | WIDTH | LEAGTH |

100/150mm | 100mm | 1220mm |

100/150mm | 100mm | 1400mm |

100/150mm | 100mm | 1500mm |

100/150mm | 100mm | 1600mm |

100/150mm | 100mm | 1800mm |